Revolutionizing Manufacturing Equipment in Texas_ The Impressive Impact of 3D Printing Technology

3D printing technology has been revolutionizing the manufacturing industry in Texas. The technology has brought with it numerous advantages, such as reduced lead time, lower production costs, customization, and scalability options, among others. Additionally, 3D printing technology has provided solutions to some of the challenges facing the manufacturing industry in Texas, such as the difficulty of sourcing replacement parts and high replacement costs. In this blog post, we delve into the impact that 3D printing technology has on the landscape of manufacturing equipment in Texas.

The Manufacturing Landscape in Texas

Texas holds a prominent position as a thriving manufacturing hub, encompassing a wide range of industries. With its strong economy, strategic location, and business-friendly environment, the state has become a magnet for manufacturing investment. Notably, the integration of advanced technologies such as 3D printing in Texas has further accelerated its manufacturing prowess.

3D printing in Texas has revolutionized production processes, offering benefits like rapid prototyping, customized manufacturing, and cost-efficient production. This technology has found applications across industries, including aerospace, automotive, electronics, and more. Texas’s status as a manufacturing hub, combined with the adoption of innovative technologies like 3D printing, has positioned the state as a leader in the manufacturing sector, fostering growth and driving innovation.

Current Challenges in Manufacturing Equipment in Texas

Despite the prominence of manufacturing in Texas, there are several challenges that the industry faces regarding manufacturing equipment. These challenges include:

- Aging Equipment: Many manufacturing facilities in Texas are operating with aging equipment that may not be as efficient or technologically advanced as newer equipment. This can lead to reduced productivity, higher maintenance costs, and potential reliability issues.

- High Replacement Costs: The cost of replacing manufacturing equipment can be significant, particularly for small and medium-sized manufacturers. High capital investments may limit their ability to upgrade or replace outdated equipment, affecting their competitiveness and productivity.

- Customization Needs: Industries in Texas often require specialized manufacturing equipment to meet their unique production requirements. The challenge lies in finding equipment that can be customized or adapted to specific processes, as off-the-shelf solutions may not always be readily available.

- Availability of Skilled Workforce: Operating and maintaining modern manufacturing equipment often requires a skilled workforce. A significant hurdle emerges when there is a deficiency of proficient workers possessing the essential technical skills required to proficiently operate, maintain, and address issues with cutting-edge equipment.

- Technological Advances: Manufacturing equipment technology is evolving rapidly, introducing new advancements such as automation, robotics, and data analytics. For certain manufacturers, keeping pace with the latest technological advancements and seamlessly incorporating them into their current manufacturing processes can present a notable challenge.

- Supply Chain Disruptions: The global supply chain encounters disturbances, as witnessed during the COVID-19 pandemic, can impact the availability of manufacturing equipment, components, and spare parts. When supply chain disruptions occur, they can result in delays in equipment maintenance, repairs, and replacements, which ultimately impact production schedules and overall operational efficiency.

Overcoming these challenges will be essential to maintaining and enhancing the competitiveness and productivity of the manufacturing industry in Texas. It will also enable manufacturers to leverage the benefits of advanced manufacturing equipment and technology to drive innovation, efficiency, and sustainable growth.

How 3D Printing is Impacting Manufacturing Equipment in Texas

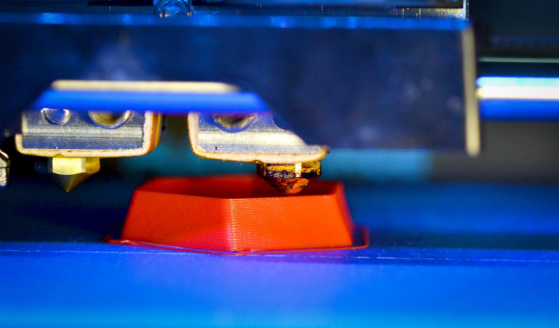

3D printing is revolutionizing the manufacturing landscape in Texas, offering a range of benefits and solutions to address the challenges faced by traditional manufacturing equipment. With its ability to create objects layer by layer based on digital designs, 3D printing is transforming the way manufacturing equipment is developed, customized, and maintained.

The impact of 3D printing in Texas can be observed in the following ways:

Benefits of 3D printing for manufacturing equipment

- Customization and Flexibility: 3D printing allows for the production of highly customized manufacturing equipment tailored to specific requirements. This capability enables manufacturers to overcome the challenge of finding off-the-shelf solutions and instead create equipment that precisely matches their unique needs.

- Reduced Lead Times: Traditional manufacturing methods often involve lengthy lead times for equipment production. 3D printing eliminates the need for complex tooling and moulds, significantly reducing lead times. Manufacturers can quickly iterate designs and produce functional prototypes in a fraction of the time, accelerating the equipment development process.

- Reduced Costs: Traditional manufacturing equipment can be costly, particularly for small and medium-sized manufacturers. 3D printing offers a cost-effective alternative, as it eliminates the need for expensive moulds, tooling, and assembly processes. Manufacturers can produce components on demand, minimizing waste and reducing overall production costs.

- Improved Efficiency and Productivity: The utilization of 3D printing enables the production of intricate, lightweight, and optimized designs that have the potential to enhance the efficiency and performance of manufacturing equipment. By utilizing 3D printing’s design freedom and advanced materials, manufacturers can enhance equipment functionality, reduce weight, and improve overall productivity.

Examples of 3D printing applications in manufacturing equipment

- Replacement Parts and Tooling: 3D printing enables the on-demand production of replacement parts, eliminating the need for large inventories or relying on suppliers for spare parts. It also facilitates the creation of customized tooling and fixtures tailored to specific manufacturing processes, further enhancing efficiency and productivity.

- Prototyping and Design Iterations: 3D printing allows manufacturers to rapidly prototype and iterate designs for manufacturing equipment. It enables quick validation of concepts, identification of design flaws, and optimization of performance before committing to full-scale production.

- On-Demand Manufacturing of Spare Parts: With 3D printing, manufacturers can produce spare parts as needed, reducing downtime caused by equipment failures or component shortages. This on-demand manufacturing approach ensures a reliable supply of critical parts, even for aging equipment.

By incorporating 3D printing services into their manufacturing processes, Texas-based companies can harness the advantages of customization, reduced lead times, cost savings, and improved efficiency. The availability of 3D printing service providers in Texas offers local manufacturers access to expertise and resources to leverage this transformative technology effectively.

Success Stories of 3D Printing in Manufacturing Equipment

- Several success stories showcase the impact of 3D printing technology on manufacturing equipment in Texas. For example, a local manufacturer adopted 3D printing technology and integrated it into their production process. The integration of 3D printing technology led to enhanced equipment performance and reduced downtime, among other benefits. The manufacturer also realized cost savings and improved supply chain management.

- Another success story is the collaborative efforts between manufacturers and research institutions in 3D printing for manufacturing equipment. Partnerships between manufacturers and research institutions have led to advancements in materials and techniques for 3D printing equipment. Additionally, these collaborations have driven innovation and competitiveness in the manufacturing industry.

Future Implications and Opportunities

- The future of 3D printing technology in manufacturing equipment is promising. Continued advancements in 3D printing technology are expected to further revolutionize the manufacturing industry in Texas.

- The technology has the potential for decentralized production and on-demand manufacturing, which could lead to increased efficiency and reduced costs.

- However, widespread adoption of 3D printing technology in manufacturing equipment has its challenges and considerations, such as the need for skilled professionals and potential regulatory issues.

Conclusion: Embracing the Transformative Potential of 3D Printing in Texas’ Manufacturing Equipment Industry

To conclude, the manufacturing equipment industry in Texas is undergoing a revolution thanks to the transformative capabilities of 3D printing technology, providing solutions to the challenges faced by manufacturers. The advantages of 3D printing in manufacturing equipment production include design flexibility and complexity, reduced lead time and production costs, customization and scalability options, and improved performance and functionality. The applications of 3D printing in manufacturing equipment include prototyping and rapid iteration, replacement parts and maintenance, tooling and fixtures, and complex and lightweight components.

Continued advancements in 3D printing technology for manufacturing equipment will lead to further growth and innovation in the industry, providing new opportunities for manufacturers in Texas.