The Impact of 3D Printing on Manufacturing in Melbourne

Over the past few years, 3D printing has surfaced as an innovative technology that holds the power to revolutionize numerous industries. One city at the forefront of this transformative wave is Melbourne, Australia. Renowned for its vibrant arts and cultural scene, Melbourne has also established itself as a thriving hub for innovation and technological advancements. With increasing businesses and institutions embracing 3D printing technology, Melbourne is experiencing a significant impact on its manufacturing sector.

The adoption of 3D printing in Melbourne has brought forth a multitude of benefits for the local manufacturing industry. One of the primary advantages lies in reducing production costs and time. Traditional manufacturing methods often involve intricate supply chains, numerous intermediaries, and substantial material wastage. In contrast, 3D printing facilitates localized production, eliminating the need for extensive transportation and logistics. By enabling faster turnaround times and minimizing material waste, businesses in Melbourne can streamline their operations and enhance their efficiency in bringing products to market.

Historical Background of Manufacturing in Melbourne

Melbourne boasts a storied history in manufacturing and has long been a prominent player in Australia’s industrial landscape. Over time, the city has witnessed remarkable advancements and transformations within the manufacturing sector.

Prior to the advent of 3D printing, traditional manufacturing methods reigned supreme in Melbourne. These methods relied on subtractive manufacturing techniques, such as cutting, drilling, and machining, to shape raw materials. While effective, these approaches often needed to be revised regarding complexity, customization, and production speed.

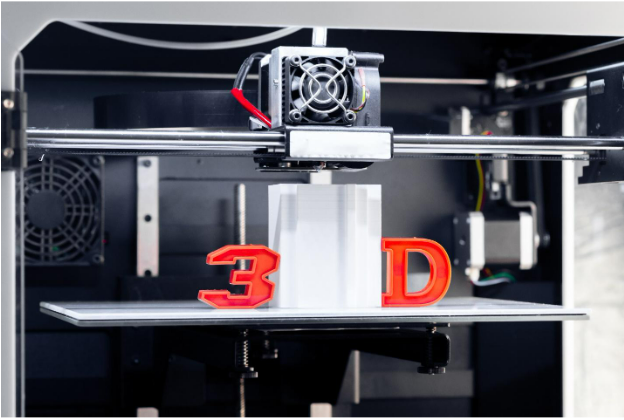

However, introducing 3D printing technology brought Melbourne’s manufacturing industry a seismic shift. Also known as additive manufacturing, 3D printing revolutionized how products were produced. This groundbreaking technology enabled the creation of three-dimensional objects by layering materials based on digital models.

The emergence of 3D printing services in Melbourne ushered in a new manufacturing era. Companies and individuals gained access to on-demand prototyping and production capabilities previously constrained by traditional manufacturing processes. The simplicity and accessibility of 3D printing services empowered designers, engineers, and entrepreneurs to swiftly and efficiently bring their ideas to fruition.

The integration of 3D printing into Melbourne’s manufacturing sector delivered numerous advantages. It facilitated heightened design flexibility, customization options, and accelerated prototyping. The technology also contributed to cost reduction, minimize material waste, and fostered sustainability. With 3D printing at its core, Melbourne established itself as a pioneering hub for manufacturing innovation throughout Australia.

Advantages of 3D Printing in Manufacturing

This cutting-edge technology offers a wide range of benefits that have transformed traditional manufacturing processes. Here are some key advantages of 3D printing in manufacturing:

- Design Flexibility: 3D printing allows for unparalleled design freedom. Unlike traditional manufacturing methods, which often have limitations and constraints, 3D printing enables the creation of complex and intricate geometries. This flexibility empowers designers and engineers to explore innovative ideas and produce custom-made products precisely.

- Rapid Prototyping: A notable benefit of 3D printing is its capacity to rapidly generate prototypes. In traditional manufacturing, prototyping can be time-consuming and costly. However, 3D printing allows rapid prototyping by quickly translating digital designs into physical objects. This accelerates the product development cycle, reduces lead times, and enables iterative design improvements.

- Cost Efficiency: 3D printing offers cost advantages in various aspects of manufacturing. Unlike traditional manufacturing methods that often involve significant tooling and setup costs, 3D printing eliminates or reduces these expenses. Additionally, it enables on-demand production, eliminating the need for mass production and excess inventory. This cost-effective approach can be particularly beneficial for small-scale production or custom-made products.

- Waste Reduction: Traditional manufacturing processes generate significant waste from subtractive methods, such as cutting or machining. On the other hand, 3D printing operates as an additive process, selectively depositing materials and minimizing waste in the process. This reduces material costs and has a positive environmental impact by promoting sustainability.

- Supply Chain Optimization: 3D printing can streamline the supply chain by enabling localized production. With traditional manufacturing, products often must be transported from various locations, resulting in long lead times and logistical challenges. 3D printing allows on-site or near-site production, reducing transportation requirements and associated costs.

- Customization and Personalization: One of the most remarkable benefits of 3D printing is its ability to create highly customized and personalized products. Each item can be tailored to individual specifications or unique requirements, allowing for a level of customization that was previously unattainable. This opens up new opportunities in sectors like healthcare, where patient-specific medical devices and prosthetics can be manufactured with precision.

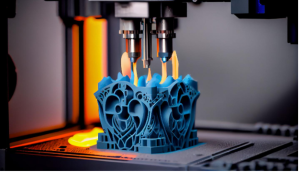

- Overcoming Complexity: 3D printing excels in producing complex geometries and intricate structures that are challenging or impossible to achieve through traditional manufacturing methods. This makes it suitable for aerospace, automotive, and architecture industries, where complicated components or designs are often required.

The advantages of 3D printing in manufacturing are vast and have the potential to reshape the industry. From enhanced design possibilities and cost savings to reduced waste and improved supply chain efficiency, this innovative technology offers a promising future for manufacturers seeking to optimize their processes and unlock new opportunities.

Applications of 3D Printing in Melbourne’s Manufacturing Industry

3D printing has found diverse applications across various sectors of Melbourne’s manufacturing industry:

- Automotive sector: 3D printing is extensively used for prototyping new vehicle designs, producing custom components, and manufacturing spare parts. This enhances efficiency in the automotive manufacturing supply chain and supports rapid innovation.

- Aerospace industry: Melbourne’s aerospace sector benefits from 3D printing by leveraging its capabilities to create lightweight components, reduce material usage, and enhance fuel efficiency in aircraft manufacturing. Additive manufacturing enables the production of complex geometries and optimized structures, leading to improved performance and reduced weight in aerospace applications.

- Medical field: 3D printing is crucial in producing customized medical implants, prosthetics, and surgical tools. Melbourne’s medical industry utilizes this technology to create patient-specific solutions, improving the effectiveness of treatments and enhancing patient comfort. By using 3D scanning and printing technologies, medical professionals in Melbourne can create personalized healthcare solutions that fit individual patient needs.

- Architecture and construction: Melbourne’s architectural and construction firms utilize 3D printing to create intricate building models, accelerate design, and explore innovative construction techniques. 3D printing allows architects to rapidly transform digital strategies into physical models, facilitating communication with clients and stakeholders. Additionally, the technology enables the production of complex and customized building components, paving the way for creating unique structures.

- Consumer Goods: The consumer goods industry in Melbourne leverages 3D printing to produce customized and personalized products. 3D printing enables manufacturers to offer unique designs and tailor-made products to meet individual customer preferences, from jewellery and fashion accessories to home decor items.

- Electronics and Electrical Equipment: 3D printing finds applications in producing casings, enclosures, and components for electronic devices. Melbourne’s electronics and electrical equipment manufacturers can leverage 3D printing to optimize designs, reduce assembly complexity, and customize products for specific applications.

- Energy and Power Generation: 3D printing can revolutionize Melbourne’s energy and power generation industry. Manufacturers can create complex and efficient components for turbines, generators, and renewable energy systems by using additive manufacturing. The ability to produce lightweight, high-performance parts improves energy efficiency and reduces maintenance costs.

Initiatives and Adoption of 3D Printing in Melbourne

Research Institutions and Innovation Hubs Powering 3D Printing Advancements

Melbourne’s dynamic ecosystem of research institutions and innovation hubs has played a pivotal role in spearheading initiatives and advancements in 3D printing. These institutions, which include universities and research centers, have recognized the immense potential of 3D printing and have allocated resources to explore its applications and push the boundaries of the technology.

Through dedicated research and development efforts, Melbourne’s research institutions have made significant contributions to the evolution of 3D printing. They have been instrumental in the development of new materials, the refinement of printing processes, and the enhancement of the technology’s capabilities. These institutions conduct comprehensive studies to optimize print quality, increase printing speed, and explore novel applications across various sectors. The collaborative spirit between researchers, engineers, and designers within these institutions has fostered a culture of innovation and excellence in 3D printing.

Collaborations between academia, industry, and government

Collaborations among academia, industry, and the government have played a crucial role in driving the adoption of 3D printing in Melbourne. These collaborations facilitate exchanging knowledge, sharing resources, and translating research into practical applications.

In Melbourne, industry leaders actively engage in partnerships with research institutions to explore the integration of 3D printing into their manufacturing processes. Through these collaborations, companies access cutting-edge research and expertise, empowering them to optimize production workflows, reduce costs, and improve product quality. Additionally, collaborating with government agencies provides essential support, funding, and regulatory frameworks that accelerate the adoption of 3D printing technology.

The collaborations between academia, industry, and the government in Melbourne have nurtured an ecosystem that promotes innovation, encourages entrepreneurship, and propels the growth of 3D printing in the manufacturing sector.

Success stories of local businesses implementing 3D printing

Melbourne has witnessed numerous success stories of local businesses that have embraced and implemented 3D printing technology. These businesses, both startups and established manufacturers, have recognized the potential of 3D printing to enhance their competitiveness, drive innovation, and offer unique products and services.

By adopting 3D printing, local businesses in Melbourne have gained a competitive edge through increased design flexibility and customization. They can produce prototypes more quickly and efficiently, allowing for rapid iteration and product development. Additionally, 3D printing has enabled these businesses to create complex geometries and lightweight structures that were previously challenging to achieve using traditional manufacturing methods.

These success stories highlight the transformative impact of 3D printing on Melbourne’s manufacturing landscape. They inspire other businesses, demonstrating the practical applications and benefits of integrating 3D printing into their operations.

The initiatives and adoption of 3D printing in Melbourne have been driven by the collaborative efforts of research institutions, industry players, and government support. These collaborations have facilitated research advancements, technology transfer, and the successful implementation of 3D printing in local businesses. As a result, Melbourne continues to position itself as a leading hub for 3D printing innovation and adoption in Australia.

Closing Thoughts on the Transformative Potential of 3D Printing

The transformative potential of 3D printing extends beyond Melbourne and has broader implications for the entire manufacturing industry in Australia. As Melbourne positions itself as a leading hub for 3D printing in the country, it sets an example for other regions. The transformative power of 3D printing lies in its ability to disrupt traditional manufacturing methods, enable rapid innovation, and empower businesses to create customized and sustainable solutions.

Melbourne’s commitment to embracing 3D printing underscores its dedication to remaining at the forefront of manufacturing innovation. By leveraging the potential of this technology, the city can attract investments, foster entrepreneurship, and nurture a skilled workforce. The transformative impact of 3D printing will continue to shape Melbourne’s manufacturing landscape, positioning the city as a global leader in additive manufacturing.

As Melbourne continues to explore and harness the capabilities of 3D printing, it will pave the way for a future where manufacturing is driven by customization, efficiency, and sustainability. The transformative potential of 3D printing is not limited to a single city but has the power to reshape the entire manufacturing industry in Australia and beyond. It promises to transform traditional supply chains, reduce waste, and enable on-demand production. This technology empowers businesses to respond quickly to market demands, optimize their processes, and offer tailored solutions to customers.